Brent

Well-known member

- Joined

- Mar 19, 2008

- Messages

- 6,091

- Reaction score

- 169

Maybe it is a Simrad settings

Sent from my iPad using Tapatalk

Sent from my iPad using Tapatalk

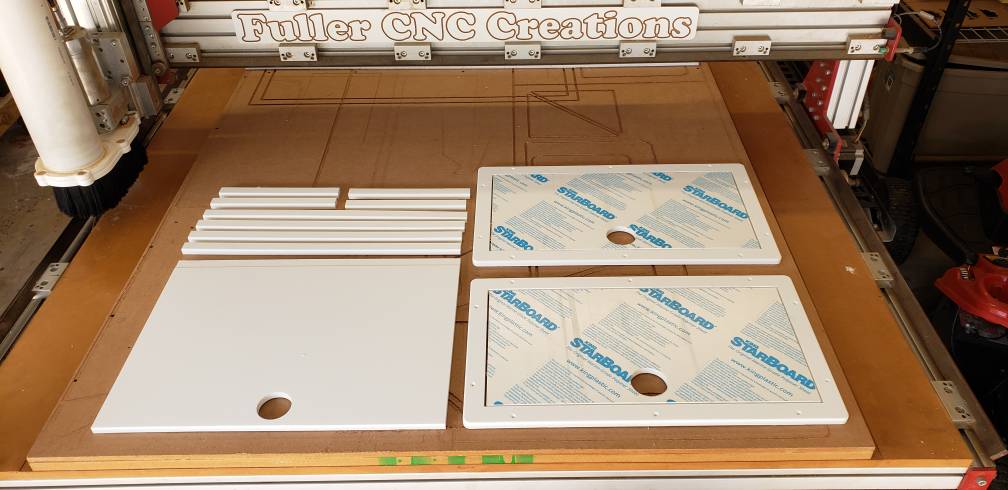

Yes it is. I'm always finding other uses for it. This one is my third machine with hopes of using it to make a living with at some point.Brent":1fkwb7j8 said:Nice and neat to have a CNC machine

Sent from my SM-G930V using Tapatalk