Then there was day 1 of teardown on Nov. 12. I copied the writeups in the posts below from my progress reports on ClassicMako and ClassicAquasport.

I decided to take advantage of a beatuiful Nov. day and really start digging into my Aquasport yesterday .

The first thing I wanted to do, was take another stab at getting the motor running. So, I drained the gear lube to see if there was any evidence of water intrustion through the prop shaft seal that was infested with fishing line. Much to my surprise, the oil that came out seemed OK.

Once that had drained, I filled with fresh gear lube and reinstalled the drain plugs with new O-rings. Then I sprayed the powerhead with CRC engine degreaser to get it cleaned up a bit. After that was done, I hooked up the battery, put on the engine muffs, connected the portable fuel tank (which now has a new line and bulb, 2.5 gals of high test, 2 oz. of Stabil (a double shot) and 5 oz. of SeaFoam) and pumped her up. To aid the battery I pulled my Jeep around and set up the jumper cables.

I crossed my fingers and hit the key. It turned over like a champ but wouldn't catch. I tried again and got the same thing. DUH, plug in the safety lanyard. So, I did that and still got nothing.

I pulled the air box cover and shot some starting fluid into the carbs. Between that and the foggin oil I sprayed in last weekend, there must have been too much liquid in there and it hydrolocked. Pulled the plugs, turned it over and got it freed up. Reinstalled the plugs, hit the key, she turned over and caught. She didn't sound good, but she ran. After about an hour on the hose, it was idling much better. Once a carb rebuild and general tune-up is are done, I think it will run really well. Compression numbers after a good warm up were 110, 106 and 111. I tried to take some shots of it running, but my camera batteries died.

While my wife went to the store to get more batteries, I attacked the gas tank cover. After cutting the caulking wity my utility knife, I was able to get one corner pried up. This allowed the water in the compartment to begin draining (you can't really see it in this picture though).

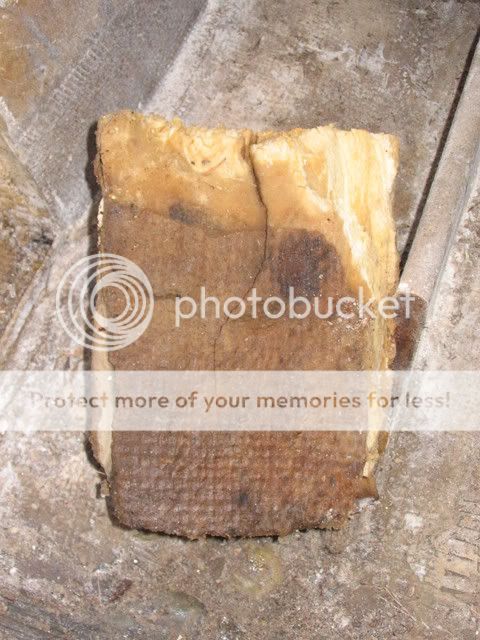

The tank cover came up after a bunch more prying and pulling. There was a nice mess underneath it...but no fuel smell or gas sheen on the water. The cover was ridiculously heavy so I imagine the core is saturated. The bottom side remained wet for quite a while....

I then proceeded unbolting steering cable and throttle from the console so I could slide it forward to get better access to the tank. Once that was done, I removed the sending unit and pumped the fuel out of the tank and into portable containers for disposal. Then I began cutting the foam and removing the clamps around the tank. From that point, I used a large steel bar I found in the yard a few years ago to gently pry on the tank to try an break it free. After about 30 minutes of prying and cutting, prying and cutting, the end of the tank popped up enough so I could get a line under it and lift it up. Then I slid it right out of it's coffin and out of the boat. The tank is actually in remarkably good condition. I suspect it was replaced a few years ago. There's only a few small pits down near the bottom.

So, this is how she currently sits. After removing the console I can begin cleaning the tank coffin. It's really nasty in there...

And the E-rude. Compared to my wife in the background, it looks like the biggest 60 HP in history. That CRC degreaser caused the paint to peel on the leg...but I didn't care. Somebody gave it a really crappy paint job sometime in the past.

After the coffin cleaning comes engine removal and then transom deconstruction.