Halleluja, I am finally done! Took her out on a sea trial yesterday and everything check out with one minor issue that I'll need to take care of (fuel sender isn't working, but I know what I did wrong). Everything else works great and there was no smoke or fire when I flipped on the power switches for the first time.

What started out as a simple project to re-organize the wiring behind the helm and run a dedicated circuit to the electronics turned into a much, much larger project. However, I am really glad I did it because I found a LOT of things wrong as I was going through things. (like uninsulated wires with twisted connections hidden behind panels!).

THANK YOU to all of you on this thread who were of so much help. There is no way I would have tackled this project on my own without knowing I had you guys to bounce ideas off of and to ask for help when I got into trouble.

Some Statistics:

Total hours spend pondering, drawing, and staring at stuff: About 60 hours

Total hours spent actually laying & terminating wires, making connections, and organizing looms: About 10 hours

Total spent on tools and components: About $1,100

Number of emergency runs to West Marine for "oh **** I ordered the wrong one and don't want to wait a week for mail order" stuff: 4

Most valuable tool:

Klein Tools 63050 9-1/2-Inch High Leverage Cable Cutter - cut everything I threw at it, including 2 AWG cable. Perfect cut every time! Runner up:

Klein D275-5 5-Inch Lightweight Flush Cutter - AWESOME for clipping cable ties flush!

Most useless tool: Micro-Therm MJ-600 mini torch. I had hoped to avoid needing 110v to power a heat gun, but this thing was useless on anything but the tiniest heat shrink. Even then it required a refill of the butane every two or three connectors to maintain max heat.

Proudest accomplishment: I eliminated the problems I was having with my fish finder by re-configuring the way the batteries were wired with the VSR.

Chief regret: I drew up a beautiful plan for all my battery connections so that I'd only have two cables per battery (in some cases using "flag" type terminals). I had boots for everything and it was going to be awesome. Except that I realized that I had bought 2/0 terminals but I have 2AWG cable. Duh! So I was forced to resort to terminating all the cables with good quality crimp-on 5/16" lugs and then stacking the lugs on the accessory posts of the batteries. Unfortunately the only 2 AWG battery terminals I can find are the ones that have a wing nut on them. :evil:

I have a few things yet to clean up (like replacing a couple of long wire runs of non-marine grade wiring for the battery charger and fixing the fuel sender wiring). The next project is installing a FLIR Navigator II and a Raymarine RD418HD radar along with a SeaTalk hs network between the two MFDs, radar, and other future gear.

DETAILS OF WORK PERFORMED:

Completely re-terminated and re-organized all wiring using AYBC approved materials and methods. Eliminated all corroded wires, replaced all terminations throughout the vessel with marine-grade tinned copper terminations and adhesive-lined heat shrink.

Re-routed all wires and cables , grouping into neat looms whenever possible

Replaced all chafed sections of wire, installing chafing guards where necessary

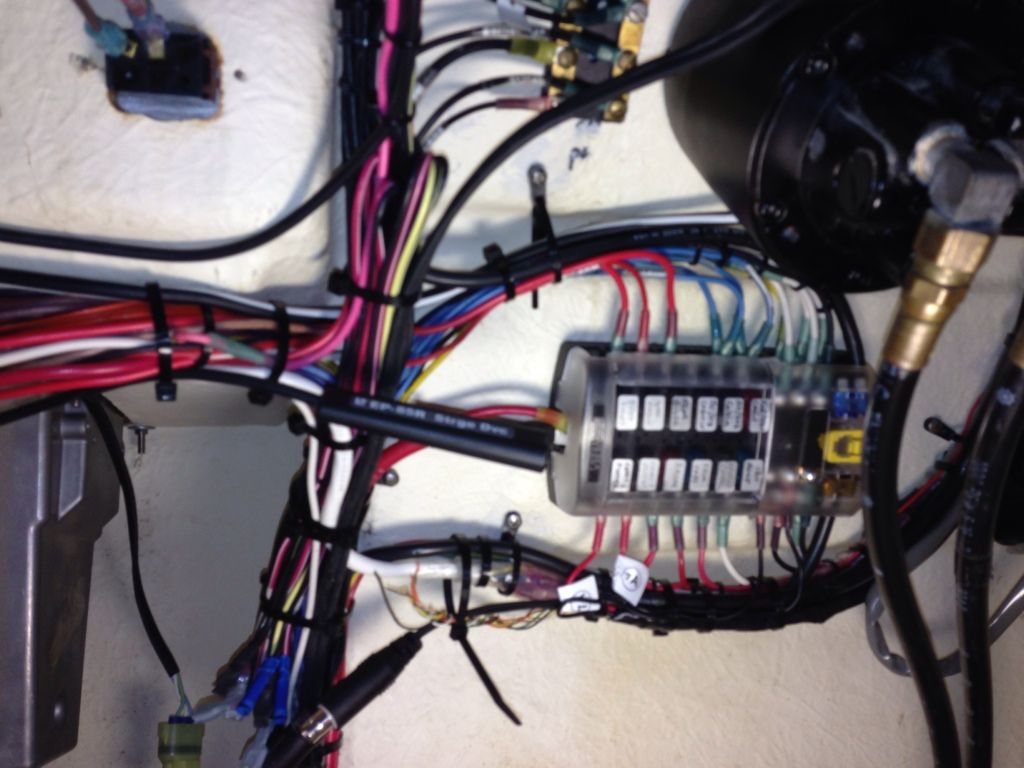

Replaced all in-line fuses with single marine grade fuse panel, properly fused according to specs for each device

Re-wired both bilge pumps so that they have a manual over-ride in addition to automatic function wired directly to the battery

Re-wired VSR so that it correctly isolates the house and starting battery banks (hopefully eliminating problems with fish finder!)

Correctly joined negative ground loop for ALL batteries using marine grade AWG 2 cable and terminations

Installed 100 amp resettable circuit breaker for helm power supply

Installed 150 amp safety fuse between two house batteries.

Installed battery cut-off switch between two house batteries

Replaced bilge hoses, installing "high loop" for back-flow prevention

CLEANED ALL OIL AND MILDEW FROM BILGE -- YECCH!

Sealed all holes in transom and dash, sealing with epoxy resin and Formula 27 (marine-grade "Bondo")

Re-wired battery charger to correctly charge all three batteries while on shore power

Replaced flimsy battery trays with AYBC compliant units, secured to boat frame with stainless hardware.

Replaced zip-cord stereo speaker wire with marine-grade AWG 16/2 shielded cable

Sealed holes in cabin roof and gunwales with epoxy and Formula 27

Repaired faulty 12v accessory socket in dash and galley area

Created "lighting bus" for navigation lights and any dash lights that we want switched on for night running

Re-wired Cockpit Courtesy Lights with their own dedicated switch and breaker

Re-wired spreader lights with their own dedicated switch and breaker

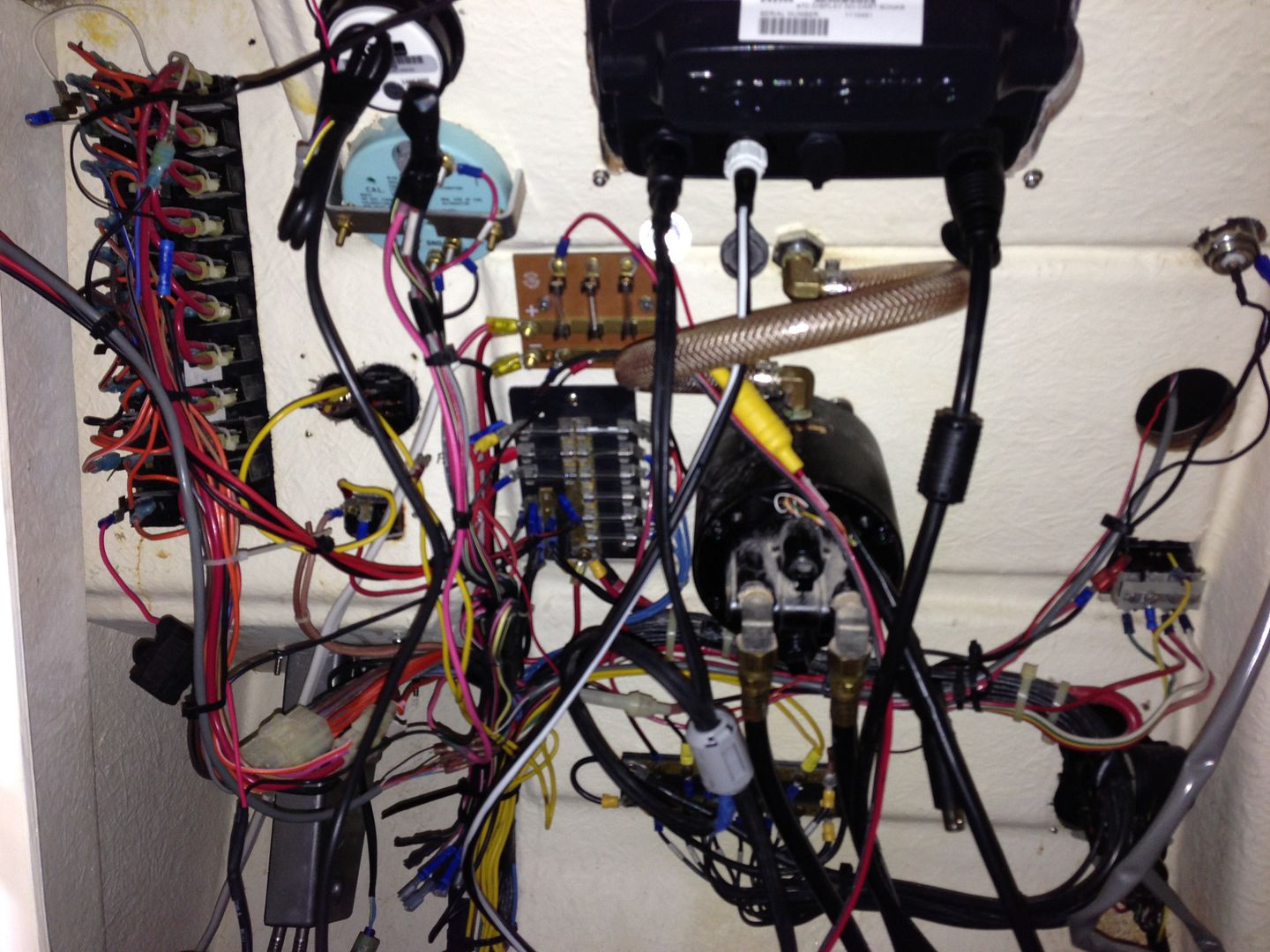

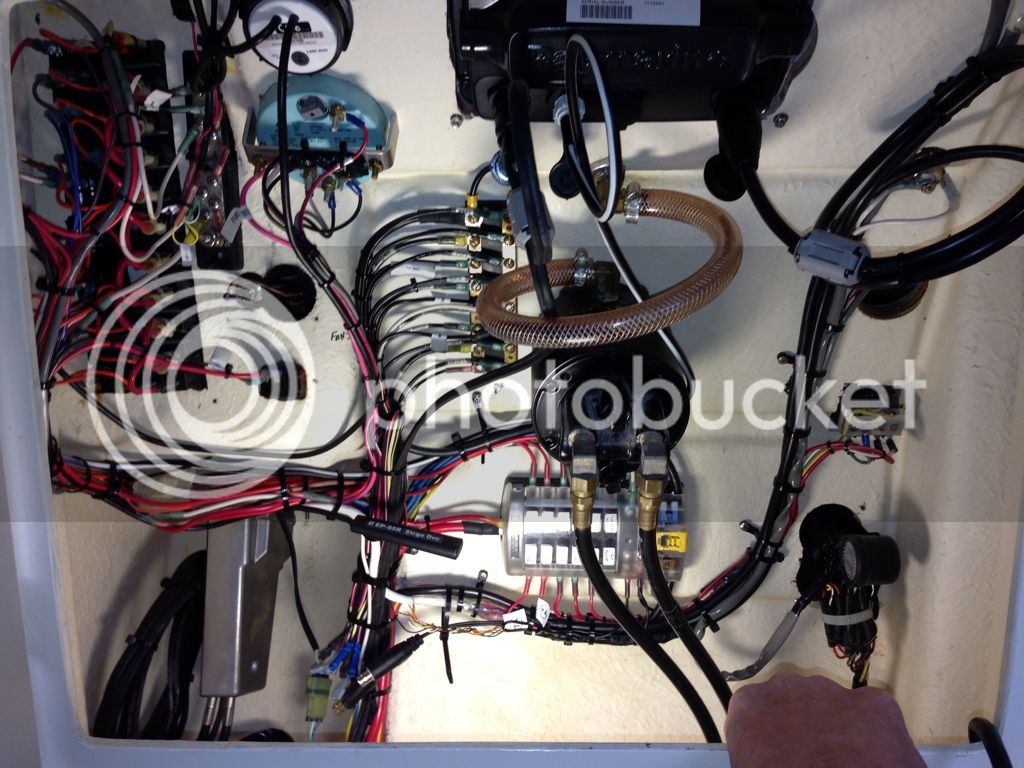

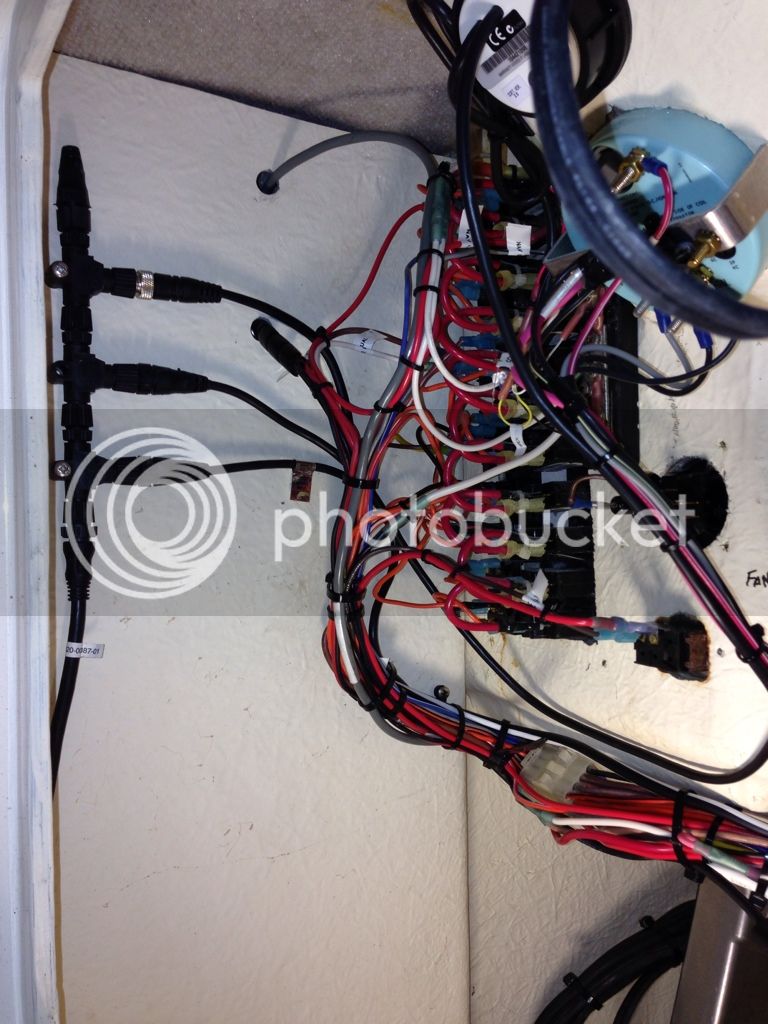

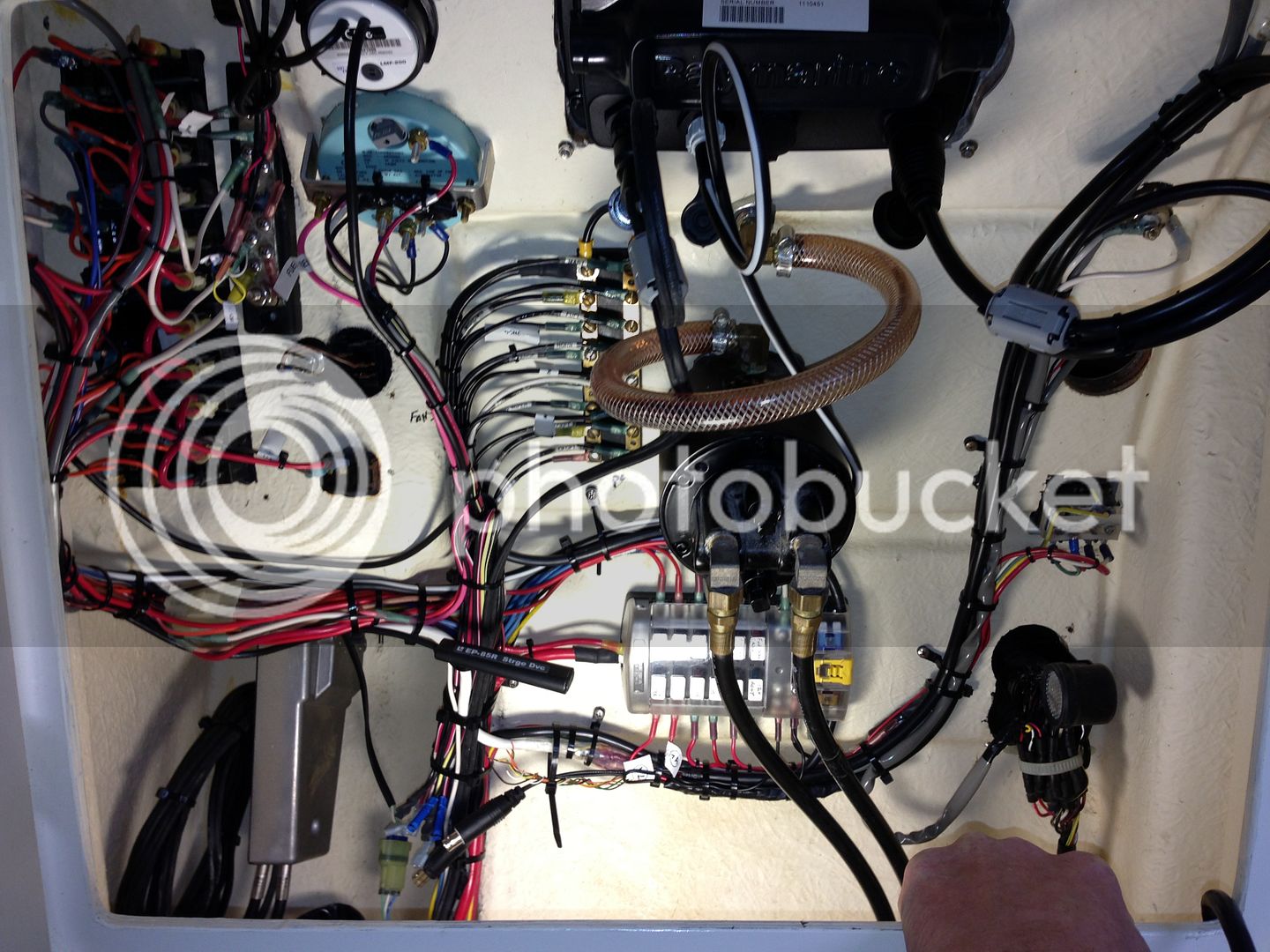

Behind the helm with everything installed:

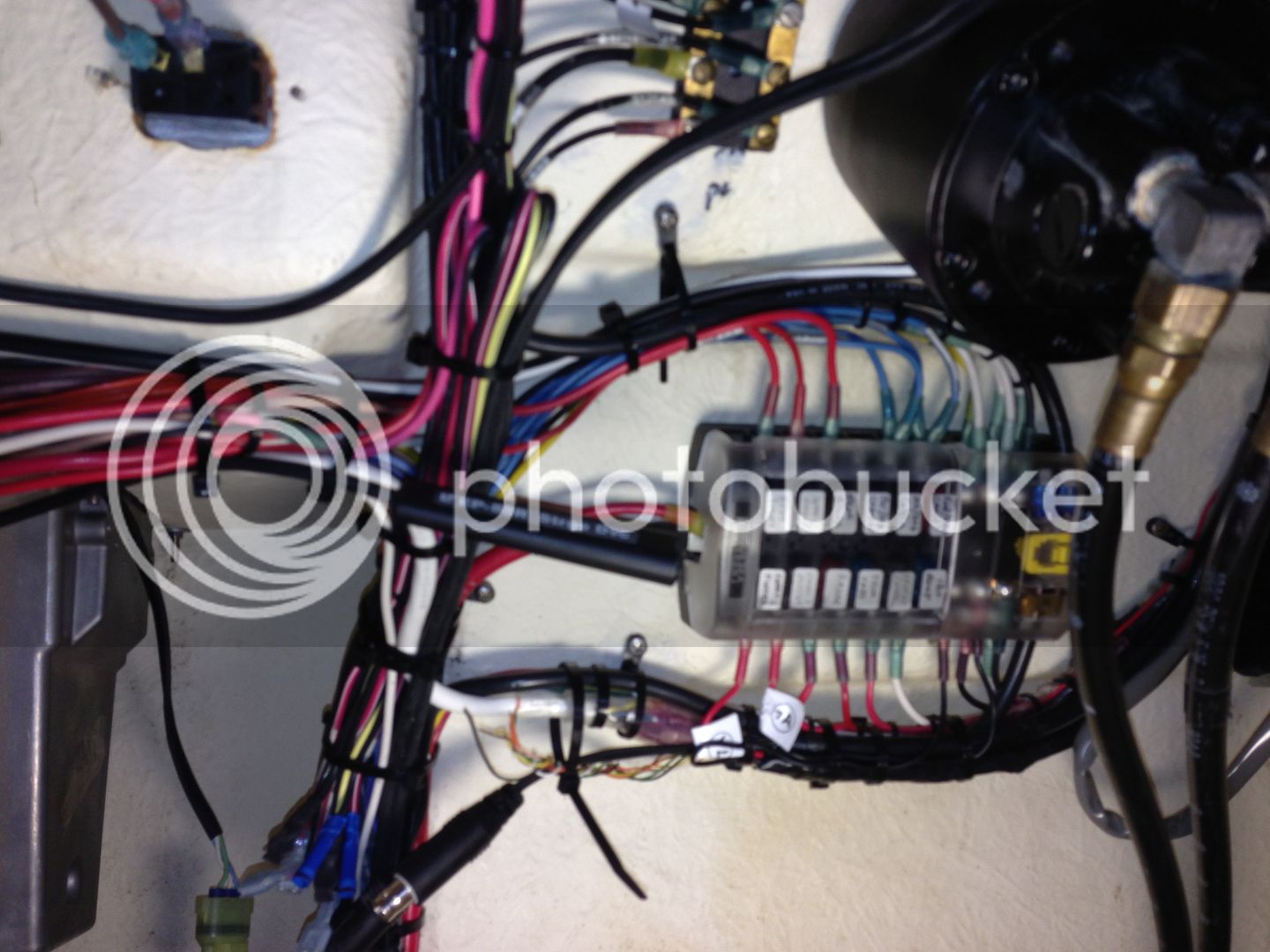

Wonderful crimpers I got from DelCity: