GW204, I can only hope mine comes out that cleanly, only putting screws "IN" though. I see dark edges, and am wondering how much cure time you gave it before taking those pics.

I stopped by West marine this morning, as I work right near the DE memorial bridge, so hopped over after work today & was there at their New Castle DE store in 10 minutes (otherwise 45 minutes from home). Manager claimed he knew Mr. Parker personally, and certainly seemed to know Parker hulls.

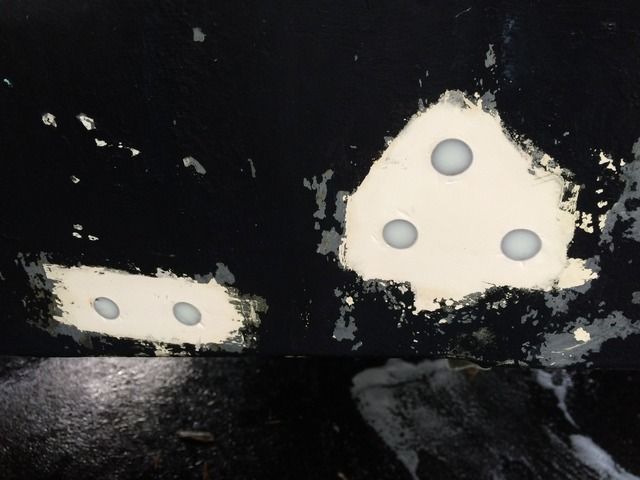

I went to pick up some 105 & 205, plus filler, but he talked me into a caulk-tube of "Six10" epoxy. he said he uses is for all holes he drills & fills. He claimed it has the same 105/205 plus colloidal silica filler. He also claimed it to have the consistency of peanut butter, but I ran some 3/4" test holes in a block of wood in a vise, and found it to be that of mayonaise or possibly thinner. I'm trying it with masking tape over the test holes during cure. Test holes are 3/4"x 1-1/4" deep, and 1-3/8" deep to accommodate 1" screws. The working time of the Six10 is very long, 42 minutes, with full load bearing in 24 hours. I want to see how it drills and holds. Will know tomorrow.