SBH2OMan

Well-known member

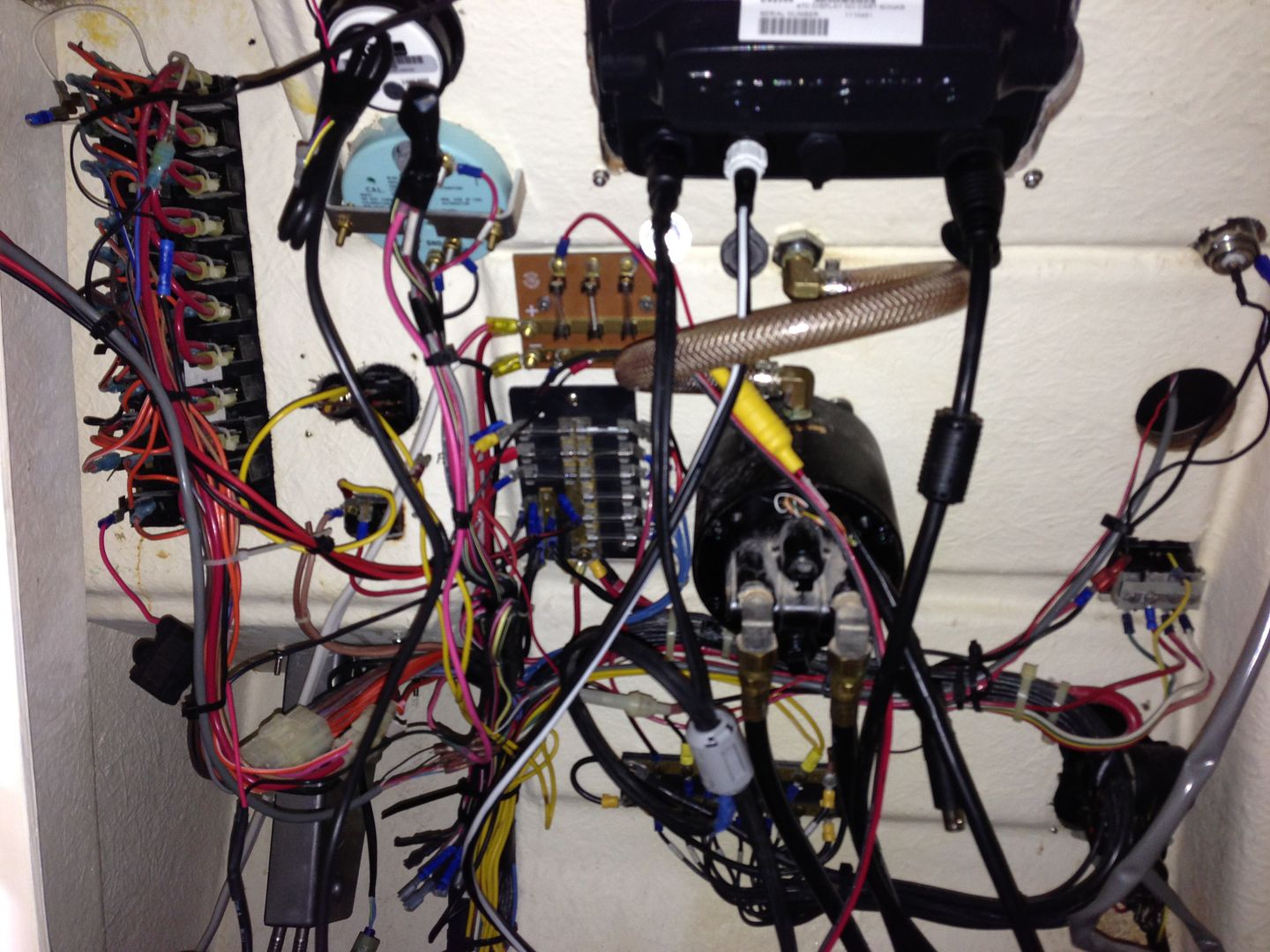

As I sit here looking at the forecast of 12' swell and 30+ knot winds over the next 10 days, I'm turning my attention to winter projects, and re-doing the accessory and light wiring is a high priority. Well, pretty much everything needs to be re-wired (or at least re-terminated and cleaned up) except for the engine and dash, which are new.

Main project goals:

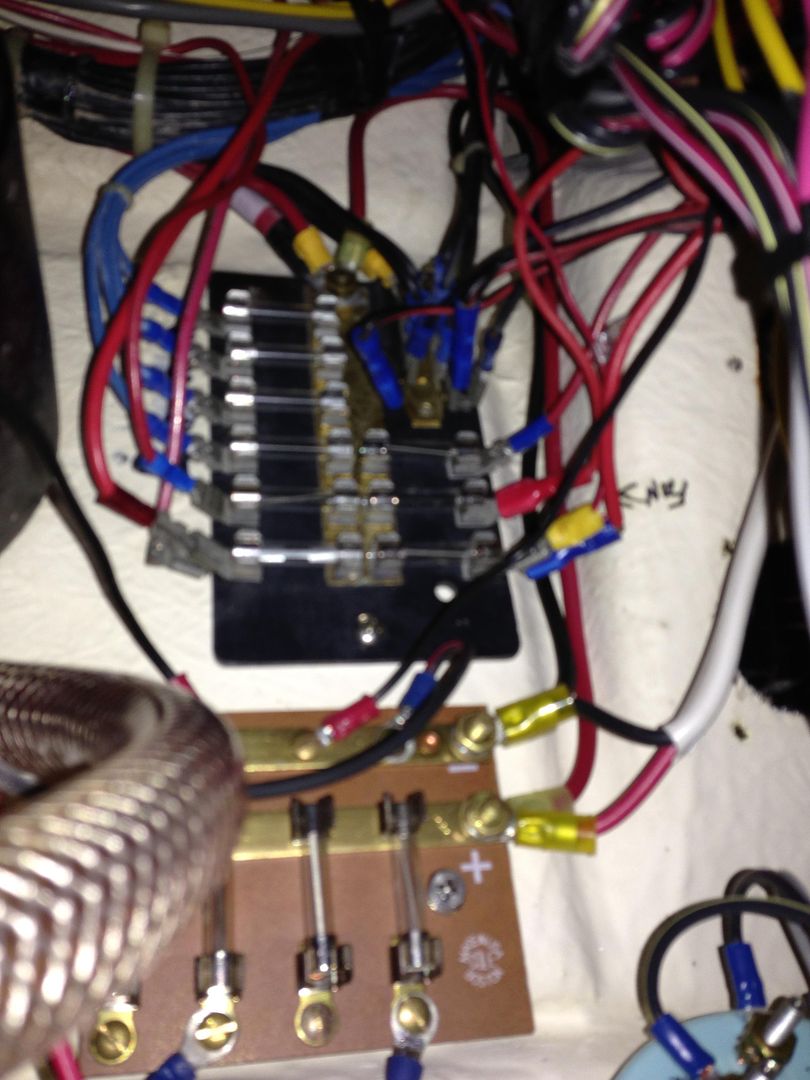

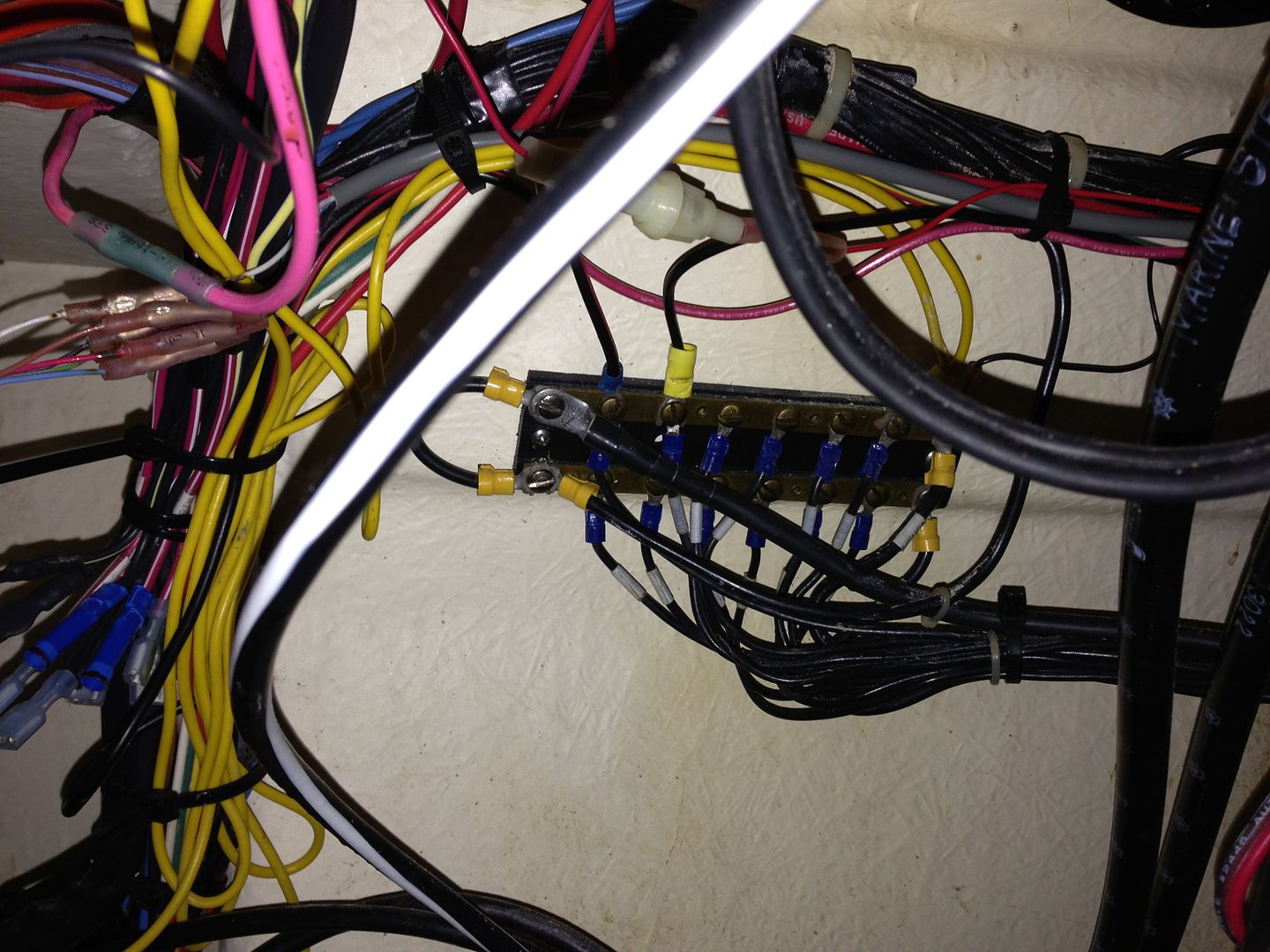

1. Move all the battery terminal connections to bus bars

2. Figure out a way to adjust lighting up and down on the dash for running in the pre-dawn hours

3. Eliminate ALL inline fuses with a single breaker & switch panel and a fuse panel for other non-switched accessories.

4. Re-wire electronics to a dedicated battery to eliminate voltage spikes from engine re-starts (causes FF to lock up)

5. Replace cabin lights with LED throughout (pilothouse and berth lights)

6. General clean up.

As I begin compiling my shopping list and planning out this job, I'm curious if anyone has found a good replacement for the original electrical switch panels that have integrated circuit breakers and good lighting?

Also, where is the best place to buy marine quality terminal connectors and wire in small bulk quantities. I get really tired of the 3-packs of butt connectors at West Marine for $4.99...

Does anyone have any other ideas I should be thinking about as part of this project?

Main project goals:

1. Move all the battery terminal connections to bus bars

2. Figure out a way to adjust lighting up and down on the dash for running in the pre-dawn hours

3. Eliminate ALL inline fuses with a single breaker & switch panel and a fuse panel for other non-switched accessories.

4. Re-wire electronics to a dedicated battery to eliminate voltage spikes from engine re-starts (causes FF to lock up)

5. Replace cabin lights with LED throughout (pilothouse and berth lights)

6. General clean up.

As I begin compiling my shopping list and planning out this job, I'm curious if anyone has found a good replacement for the original electrical switch panels that have integrated circuit breakers and good lighting?

Also, where is the best place to buy marine quality terminal connectors and wire in small bulk quantities. I get really tired of the 3-packs of butt connectors at West Marine for $4.99...

Does anyone have any other ideas I should be thinking about as part of this project?

![Garmin ECHOMAP UHD2 53CV Chartplotter/Fishfinder with US Inland Maps and GT20-TM [010-02590-51]](https://m.media-amazon.com/images/I/314dMbaaLhL._SL500_.jpg)