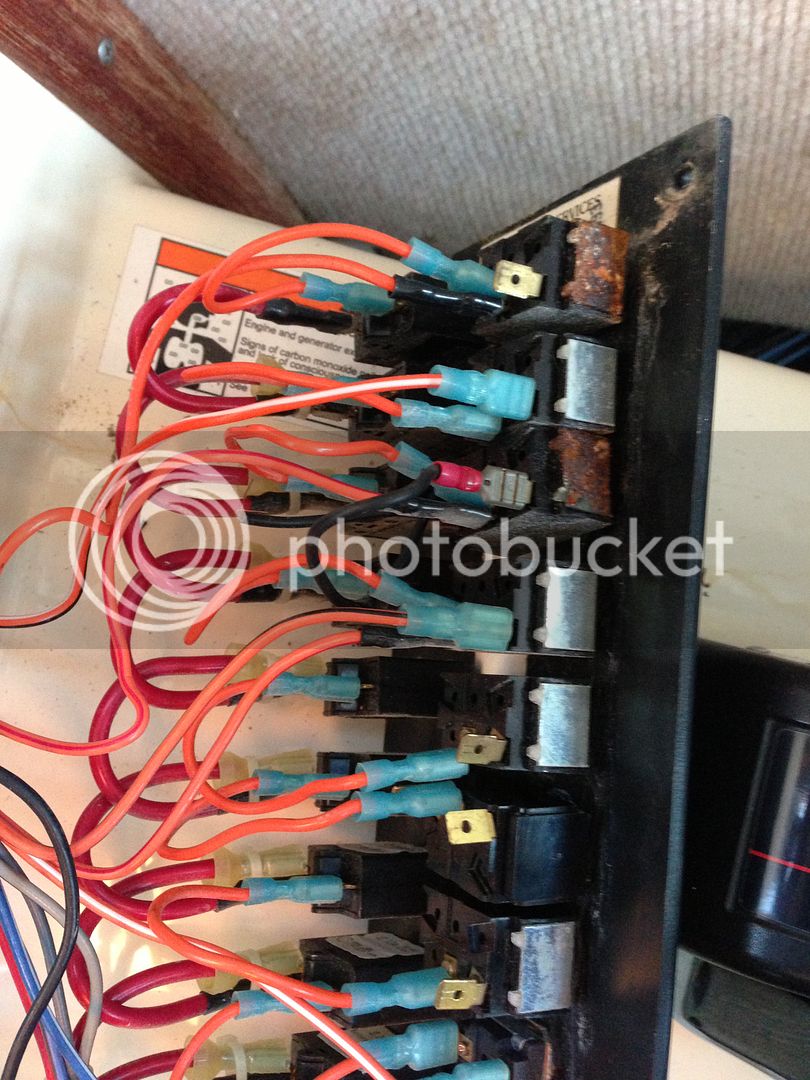

Sometimes you just have to rip it out and start over, if for nothing else than to know it's done right.

FWIW... When I worked on an airfield, stuff that could get sucked into an aircraft engine or puncture a tire was called "FOD" (foreign object damage).

FOD in a boats bilge can find it's way to the bilge pump and totally ruin your day. :shock:

As you discovered, old zip-ties and hardware make their way into the pump and can cause a catastrophic failure, and it will always happen at the worst possible moment.

FWIW... When I worked on an airfield, stuff that could get sucked into an aircraft engine or puncture a tire was called "FOD" (foreign object damage).

FOD in a boats bilge can find it's way to the bilge pump and totally ruin your day. :shock:

As you discovered, old zip-ties and hardware make their way into the pump and can cause a catastrophic failure, and it will always happen at the worst possible moment.